Lepu Seal - A Professional China Mechanical Seal Manufacturer providing Cartridge Seal, Grundfos Mechanical Seal And We offer free sample!

solid mesh Blackmer Seal gx OEM for high-pressure applications

1. Lepu Blackmer Pump Seal Factory is meticulously produced. Its manufacturing processes include areas such as computerized machine control, engineering statistics, ergonomics, and life cycle analysis. Lepu seals are designed and manufactured rigorously

2. The use of this high-tech product reduces the number of unskilled workers needed in the production process. Besides, it also raises productivity. Compact gland allows Lepu seal to be used in limited space

3. Blackmer Pump Seal Factory can be seen in this Blackmer Seal which can Mechanical Seal for Blackmer Pump. With highly advanced technology, Lepu seals can ensure better productivity for you

4. To satisfy the needs of our customers, we additionally design the performance which is Blackmer Pump Seal Factory . Lepu has strict requirements in the production process

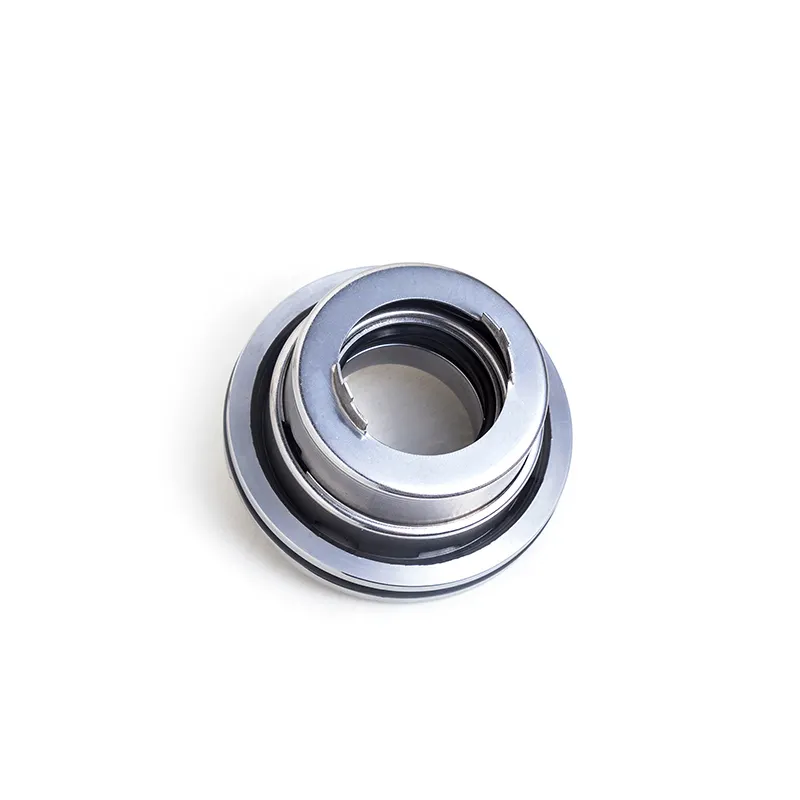

This blackmer mechanical seal is designed for blackmer TX series pump, and the mechanical seal is working for Clean, non-corrosive industrial liquids and petroleum products. Typical applications include fuel oils, lube oils, jet fuels, gasoline, edible oils.

This blackmer seal use cast iron for the frame with cartridge seal design, easy to install and maintain. Rotary and stationary seal parts normally use carbon and SIC, the secondary seal part is BUNA or EPDM.

PRODUCT ADVANTAGE

PRODUCT TECHNICAL SPECIFICATION

◪ Standard or Nonstandard: Standard

◪ Model Number:BLC-35

◪ Sealing Face: Carbon, SSIC

◪ Other P/N of

◪ Seal:331601/331628/331602/331673/331648/331880/331872/331882/331873/331899/336958/331973/331652/335225/332050/

PRODUCT APPLICATION

◪ Blackmer mechanical Seals fits for blackmer Pump.

◪ For a GX and X and Pumps Used in models: , XH2.5B, TX1.5, TXD2A, TX2A, TXD2.5A, TX2A, TXD2.5A, TX2.5A, TX1220A, TX1225A

DISPLAY DIAGRAM

Guangzhou Lepu machinery CO., LTD becomes one of the leading mechanical seal supplier in south of china, we focus in designing and manufacturing mechanical seal for many kinds of famous brand pumps, our mechanical seal cover many kinds of industry like food, petrol chemical, paper making, sea ship, and so on.

Company Features

1. Guangzhou Lepu Machinery CO., LTD has been committed to technology innovation and Blackmer Pump Seal Factory since the day of its inception. The quality for our Blackmer Seal is so great that you can definitely rely on.

2. We have the capability of researching and developing state-of-the-art technologies of Blackmer Pump Seal .

3. All our Blackmer Seal have conducted strict tests. Our Company is built on the foundation of essential values that serve as the cornerstone to our ambition of achieving a strong, sustainable, harmonious and profitable growth. These values establish the charter of our company's past and future.

Guangzhou Lepu Machinery Co., Ltd.

Add:

No. 5, Yunkai Road, Huangpu District, Guangzhou, China

Tel:

+86-020-36158139

+86-020-36158280

E-mail:

mark@lepuseal.com

Fax: +86-020-36158281

Contact Person: Mr. Mark Ao

Whatapps: +86-18903009893