Lepu Seal - A Professional China Mechanical Seal Manufacturer providing Cartridge Seal, Grundfos Mechanical Seal And We offer free sample!

Lepu Seal High-quality dry gas seals for centrifugal compressors Suppliers

Main Features for Pump Dry Gas Seal:

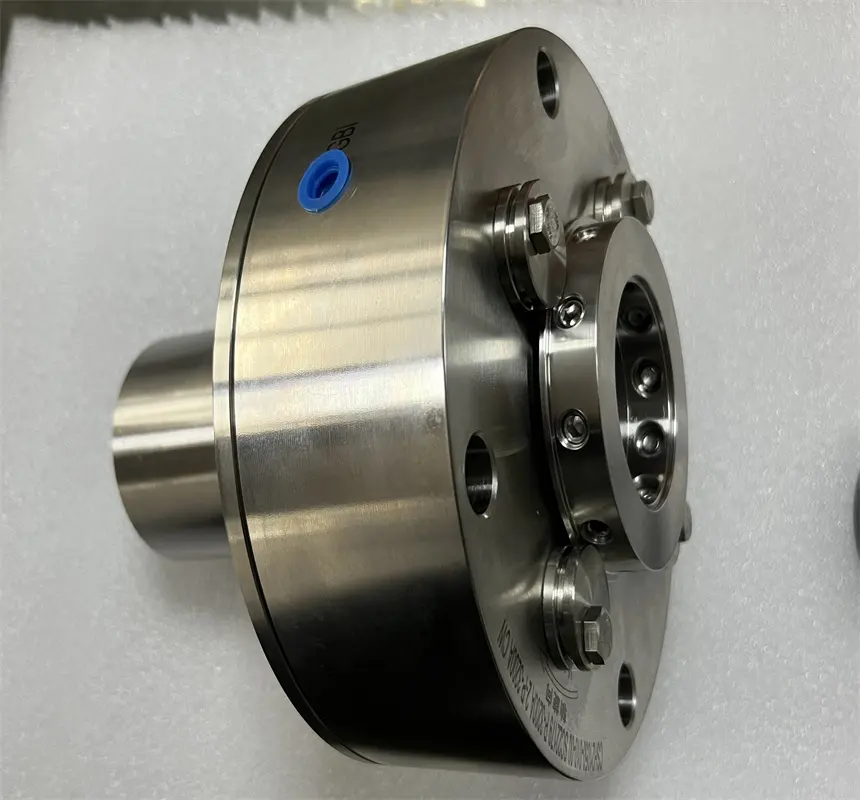

1. It is composed of two sets of single-end dry gas seals. The principle of "gas blocking" is used instead of "liquid blocking", and the medium is sealed with a sealing gas with a pressure higher than the sealing cavity pressure of 0.2 ~ 0.3Mpa to ensure that the process medium achieves zero environment Escape, meet VOC emission requirements, safety and environmental protection.

2. A small amount of sealing gas has entered the process. The seal has high requirements on the pressure of the sealed air source. It must be higher than the pump cavity pressure at any time without interruption.

3. The seal adopts cartridge type, convenient installation and disassembly, non-contact operation, energy saving, safety and environmental protection, reliable performance, simple operation, and an average service life of up to 3 years.

4. Double seal design, and back to back, fit for long shaft chemical pump.

Working Specifications:

Pressure: 0 ~ 4MPa

Temperature: -104 ~ 260 ℃

Speed: ≤3600r / min

Applicable working conditions:

Suitable for various fluid media, mainly used for toxic and harmful, high temperature, easy coking, easy self-aggregation, strong corrosion, granular media, etc. Such as H2S fluid media, solvents, benzene, quench oil, tar, methanol, etc.

Benefit for pump dry gas seal:

The dry gas sealwas simple, This technology is usually not used in liquid-pump applications, but it seemed to be a good solution because the ethane liquid wants to be a gas.

Dry gas seals delivered enhanced reliability in operating modes where the seal faces are in constant contact—turning, ratcheting, coast-down and other operating modes that create critical conditions for standard gas seals. Experience has shown that unexpected operating situations, such as the transient conditions the end user was experiencing, can compromise a gas seal.

Because seal faces are designed primarily for non-contact operation, they are subject to wear when there is contact for sustained periods. This can cause seal failure resulting in downtime and production loss.

This technology also provided simplification of the sealing system. In this application, the liquid ethane is very clean. It is typical to filter the ethane prior to injecting it back in the seal area; otherwise, there is a risk of damage to the dry gas seal faces. A filter flush can increase the stuffing box pressure, which increases the vapor margin and makes it more difficult to vaporize the liquid.

Instead of using a flush, if some particles were in the liquid, the special bonding would either crush them, or if they are small enough, the special dry gas seal groove pattern would pass them along. No filters were needed, which reduced maintenance costs and downtime.

Why buy dry gas seal from LEPUSEAL?

Lepuseal is one of the top 10 brand for mechancial seal products, especially for cartridge seal and dry gasl, Lepuseal located in Guangzhou, China, a huge city with more than 2000 mililon population, and Lepuseal is one of the high-technology company, which endorsed by Guangzhou government.

Lepuseal focus one mechanical seal since 1998, making mechanical seal include dry gas seal for many clients from different countries, more than 100 countries user had used mechanical seal from lepuseal, and offer positive feedback.

if compared the world famous brand for dry gas seal, like ealgeburgmann, john crane, aesseal, flowserve and so on. lepuseal can offer similar quality, but with cheaper price, and faster delivery. those are the main reason more and more users buy dry gas seal from China LEPUSEAL.

PRODUCT ADVANTAGE

PRODUCT TECHNICAL SPECIFICATION

ressure: 0 ~ 4MPa

Temperature: -104 ~ 260 ℃

Speed: ≤3600r / min

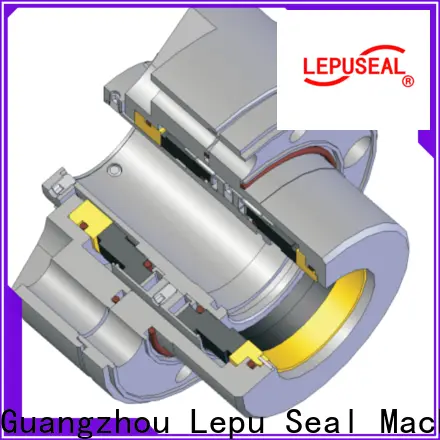

DISPLAY DIAGRAM

Guangzhou Lepu machinery CO., LTD becomes one of the leading mechanical seal supplier in south of china, we focus in designing and manufacturing mechanical seal for many kinds of famous brand pumps, our mechanical seal cover many kinds of industry like food, petrol chemical, paper making, sea ship, and so on.

Guangzhou Lepu Machinery Co., Ltd.

Add:

No. 5, Yunkai Road, Huangpu District, Guangzhou, China

Tel:

+86-020-36158139

+86-020-36158280

E-mail:

mark@lepuseal.com

Fax: +86-020-36158281

Contact Person: Mr. Mark Ao

Whatapps: +86-18903009893