Dry Gas Seal

The advantages and working principle of the labyrinth spiral seal of the spiral seal

by:Lepu Seal

2021-06-08

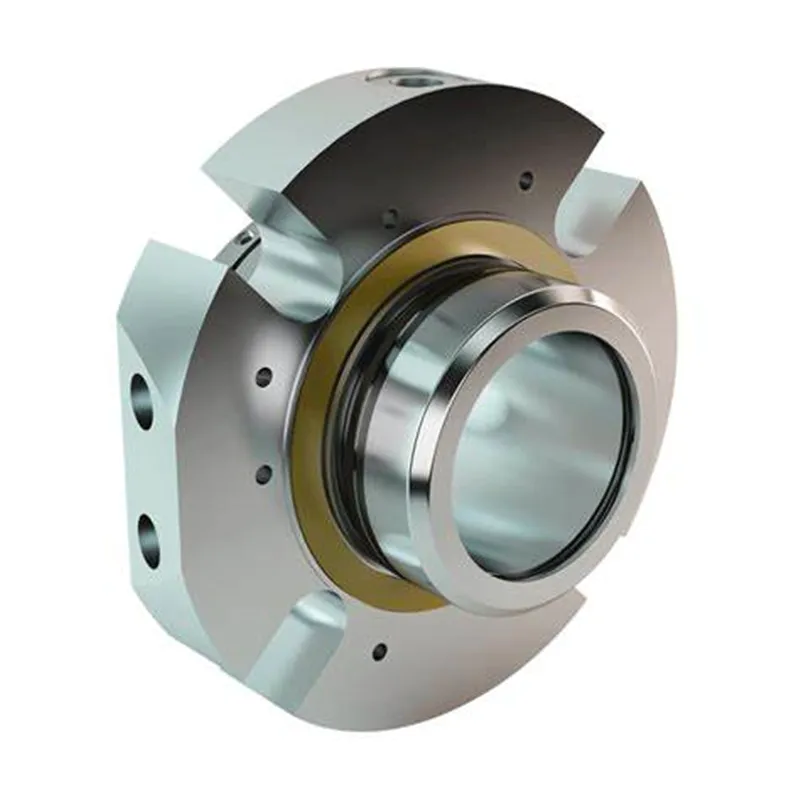

The advantages and working principle of the labyrinth spiral seal of the spiral seal The spiral seal is used in many cutting-edge technology departments, such as the compressor seal of the air-cooled reactor, the sodium pump seal of the breeder reactor, etc. Sometimes it is also used to seal the high speed shaft of the reducer. The biggest advantage of the spiral seal is that even if there is a large gap between the sealing parts, it can effectively seal. If the spiral seal is designed reasonably, the service life of the mechanical seal can reach infinity. Because it can choose from a wide range of materials and is extremely easy to manufacture, when the pressure difference is not large, the power loss and heat generation of the spiral seal are small, and the cooling water jacket is sufficient to dissipate heat. Spiral seals often need to be supplemented with parking seals, which complicates the structure and increases the size, so the application of mechanical seals for spiral seals is often restricted. Spiral seal can be used for high temperature, deep cold, corrosion and liquid with particles, etc., the sealing conditions are harsh, and the sealing effect is good. Labyrinth spiral seal has been used in industry for a long time. The difference between it and spiral seal is that the mechanical shaft seal has a spiral groove on the surface of the shaft, and a screw sleeve is also machined on the sealed hole. The opposite thread direction causes the flow between the shaft and the screw sleeve to form a strong turbulence. In addition, the spiral motion speed of the labyrinth spiral seal is higher than that of the screw seal. The labyrinth spiral seal is used for low-viscosity liquids under turbulent flow conditions. Spiral seals are generally used for high-viscosity liquids (such as liquids with a viscosity greater than water) under laminar flow conditions. The working principle of the labyrinth spiral seal: In the working space between the screw and the screw sleeve, the liquid is located in several honeycomb-shaped spaces surrounded by the two tooth surfaces of the screw sleeve and the two tooth surfaces of the screw. The gap between the surface of the screw and the screw sleeve is an annular cylindrical surface with grooves. When the liquid passes through these threads, a vortex is formed, and the direction is opposite to the outflow direction. As a result of the momentum exchange of the liquid flowing around the screw, the screw transfers energy to the liquid. The screw and screw sleeve interact with the liquid, resulting in friction at the nominal interface passing through the gap between the screw and screw sleeve. The friction generated in the liquid creates pressure between the screw and the screw sleeve. Keywords: mechanical seals, mechanical seals, mechanical shaft seals

Custom message