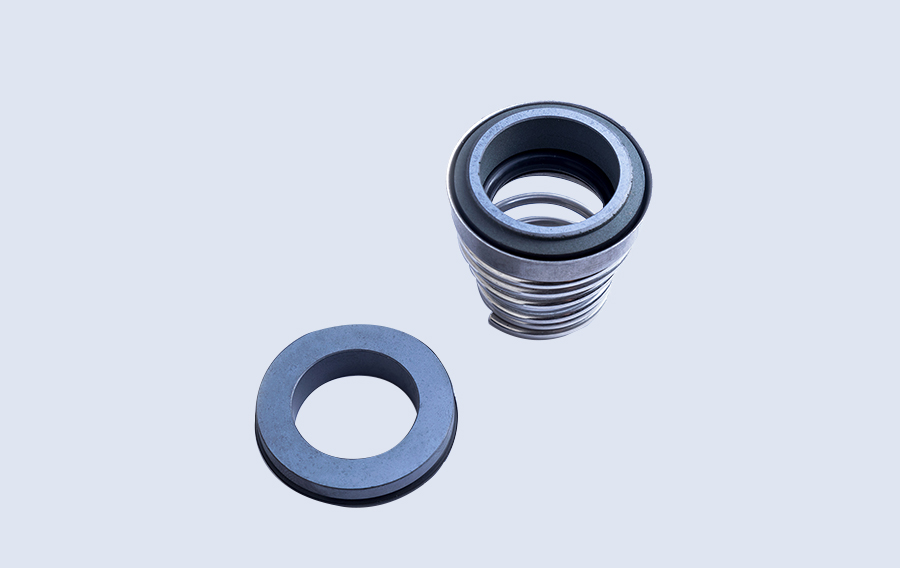

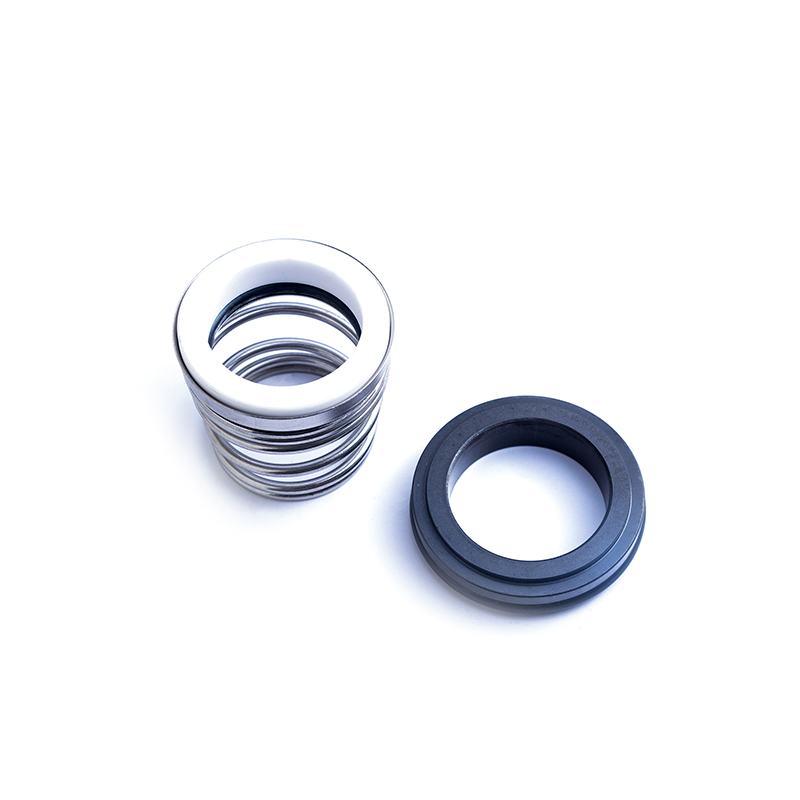

Single spring mechanical seal 155(155B) is a very economic mechanical seal, highly valuable and with interchangeable components.

As a low cost seal, mechanical seal 155 is used for many famous pump, like lowara pump, flowserve pump, and so on. It is easy to replace and maintain.

The popular material are ceramic ,carbon, silicon for the seal ring, and stainless steel for the frame and single spring .

Lepu seal factory provides this mechanical seal 155 to many different clients with big quantity, and get high reputation when making this seal 155, buy mechanical seal from our factory is a good choice.

Advantage introduction:competitive price+ fast delivery+top after-sale service

◪ Sealing Face: Carbon, SIC, TC, Ceramic

◪ Secondary Sealing Combination: NBR, EPDM, VITON

◪ Sealing Frame: stainless steel

◪ Working Temperature:-20℃ --- 180℃

◪ Working pressure: ≤ 0.8MPA

◪ Linear Speed:≤ 10m/s

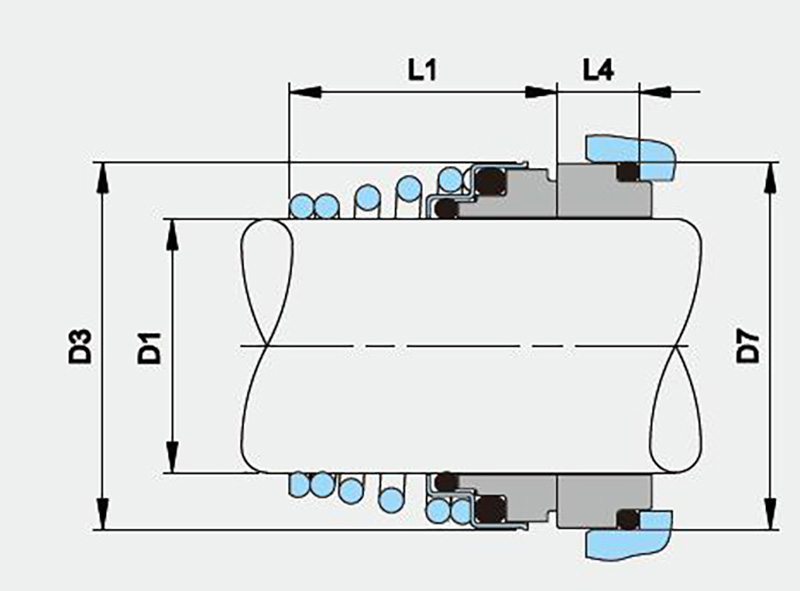

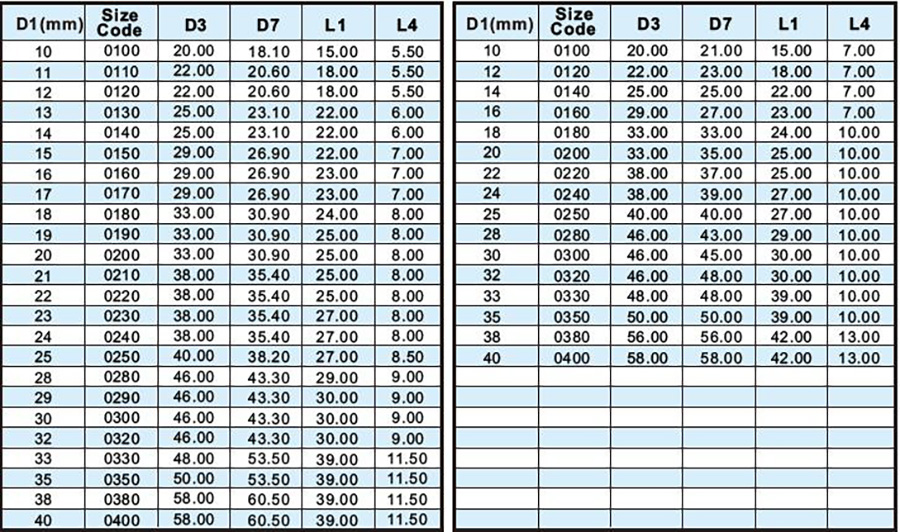

Specification and size : 155/155B

Working for water pump like lowara flowserve, KSB pump.

Guangzhou Lepu machinery CO., LTD becomes one of the leading mechanical seal supplier in south of china, we focus in designing and manufacturing mechanical seal for many kinds of famous brand pumps, our mechanical seal cover many kinds of industry like food, petrol chemical, paper making, sea ship, and so on.

Copyright © 2018 Guangzhou Lepu Machinery CO., LTD. | All Rights Reserved Design by www.lepuseal.com

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.