Mechanical seal knowledge

by:Lepu Seal

2022-09-14

Mechanical seal knowledge

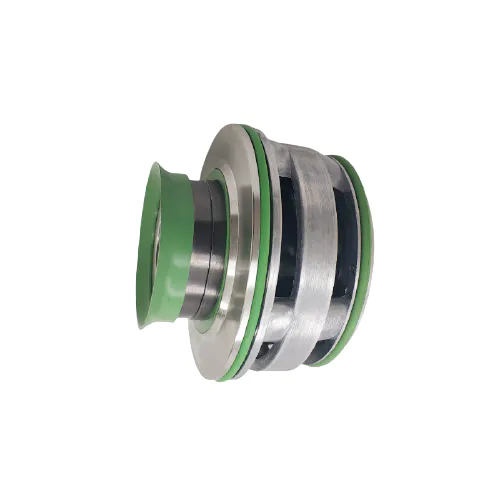

Mechanical seals are one of the most sophisticated and complex mechanical basic components, and are key components of various pumps, reaction components, turbocompressors, submersible motors and other equipment. Its sealing function and service life depend on many factors, such as model selection, machine accuracy, accurate installation and application of Grundfos mechanical seals, etc. 1. Installation and application requirements of mechanical seals 1. The requirements of mechanical seals for machine accuracy (taking pump mechanical seals as an example) (1) The radial runout tolerance of the shaft (or shaft sleeve) of the imported mechanical seal in the installation of the mechanical seal is the largest Do not exceed 0.04 ~ 0.06mm. (2) The axial movement of the rotor does not exceed 0.3mm. (3) The runout tolerance of the cartridge mechanical seal between the positioning end of the sealing cavity and the sealing end cover facing the surface of the shaft (or shaft sleeve) should not exceed 0.04-0.06mm at most. 2. Confirmation of seals (1) Confirm whether the installed seal is the same as the required type. (2) Before installation, carefully check with the general assembly drawing to see if the number of parts is complete. (3) The mechanical seal driven by the parallel spring is selected, and the spring has left and right rotation, which must be selected according to the rotation history of the rotating shaft. Second, the selection method of mechanical seals according to the working conditions and the properties of the medium are different, there are high temperature and low temperature mechanical seals, high pressure and corrosion resistance mechanical seals, particle medium mechanical seals and mechanical seals that are used to easily vaporized light hydrocarbon media Seals, etc., mechanical seals with different structural types and materials should be selected according to different uses. The main parameters of the selection are: sealing cavity pressure (MPa), fluid temperature (°C), working speed (m/s), fluid characteristics and useful space for sealing installation. The basic principles of selection are: 1. According to the pressure of the sealing cavity, determine whether the sealing structure is balanced or unbalanced, single-end or double-end, etc. 2. According to the working speed, determine the choice of rotary or stop type, fluid dynamic pressure type or non-touch type. 3. According to the temperature and fluid properties, determine the conflicting pair and auxiliary sealing materials, and accurately select the mechanical seal circulation protection system such as smoothing, scouring, heat preservation, cooling, etc. 4. According to the effective space of the installation and sealing, determine the choice of multi-spring or single-spring or wave spring, built-in or external-mounted. 3. The installation method varies with the type of mechanical seal and the variety of the machine, but the installation method is almost the same. The installation process and precautions are as follows: (1) When the installation size is determined, it should be installed according to the product size. Use the instructions or samples to ensure the installation size of the mechanical seal. (2) Before loading, the shaft (sleeve) and gland should be free of burrs, and the bearing should be in good condition; the seals, shaft, sealing cavity and gland should be cleaned. In order to reduce the conflict resistance, the part where the mechanical seal is installed on the shaft should be coated with a thin layer of oil for smoothness. Considering the compatibility of the rubber O-ring, if oil is not suitable, soapy water can be applied. The structure of the floating static ring without anti-rotation pin should not be oiled, and should be installed in the gland dry. (3) Install the static ring together with the gland on the shaft first, taking care not to collide with the shaft, and then install the moving ring assembly. The set screw of the spring seat or transmission seat should be tightened evenly in several times. Before the gland is not fixed, push the compensating ring by hand for axial tightening. After loosening, the compensating ring can automatically spring back without jamming, and then lock the gland bolts evenly. 4. Application (1) When the temperature of the transport medium is too high, too low, or rich in impurity particles, flammable, explosive, or toxic, it is necessary to take corresponding measures such as blocking, flushing, cooling, and filtering. (2) Turn the car by hand before running, pay attention to whether the torque is too large, whether there is friction or abnormal sound. (3) Pay attention to the direction of rotation, whether the coupling is centered, whether the addition of lubricating oil in the bearing part is appropriate, and whether the piping is accurate. (4) Before operation, first open the medium and cooling water valves to check whether the gas in the sealed chamber is completely discharged, so as to avoid leakage caused by static pressure, and then start the operation. (5) Whether the work is normal and stable after driving, whether there is abnormal torque caused by shaft rolling, abnormal noise and overheating.

Mechanical seals are one of the most sophisticated and complex mechanical basic components, and are key components of various pumps, reaction components, turbocompressors, submersible motors and other equipment. Its sealing function and service life depend on many factors, such as model selection, machine accuracy, accurate installation and application of Grundfos mechanical seals, etc. 1. Installation and application requirements of mechanical seals 1. The requirements of mechanical seals for machine accuracy (taking pump mechanical seals as an example) (1) The radial runout tolerance of the shaft (or shaft sleeve) of the imported mechanical seal in the installation of the mechanical seal is the largest Do not exceed 0.04 ~ 0.06mm. (2) The axial movement of the rotor does not exceed 0.3mm. (3) The runout tolerance of the cartridge mechanical seal between the positioning end of the sealing cavity and the sealing end cover facing the surface of the shaft (or shaft sleeve) should not exceed 0.04-0.06mm at most. 2. Confirmation of seals (1) Confirm whether the installed seal is the same as the required type. (2) Before installation, carefully check with the general assembly drawing to see if the number of parts is complete. (3) The mechanical seal driven by the parallel spring is selected, and the spring has left and right rotation, which must be selected according to the rotation history of the rotating shaft. Second, the selection method of mechanical seals according to the working conditions and the properties of the medium are different, there are high temperature and low temperature mechanical seals, high pressure and corrosion resistance mechanical seals, particle medium mechanical seals and mechanical seals that are used to easily vaporized light hydrocarbon media Seals, etc., mechanical seals with different structural types and materials should be selected according to different uses. The main parameters of the selection are: sealing cavity pressure (MPa), fluid temperature (°C), working speed (m/s), fluid characteristics and useful space for sealing installation. The basic principles of selection are: 1. According to the pressure of the sealing cavity, determine whether the sealing structure is balanced or unbalanced, single-end or double-end, etc. 2. According to the working speed, determine the choice of rotary or stop type, fluid dynamic pressure type or non-touch type. 3. According to the temperature and fluid properties, determine the conflicting pair and auxiliary sealing materials, and accurately select the mechanical seal circulation protection system such as smoothing, scouring, heat preservation, cooling, etc. 4. According to the effective space of the installation and sealing, determine the choice of multi-spring or single-spring or wave spring, built-in or external-mounted. 3. The installation method varies with the type of mechanical seal and the variety of the machine, but the installation method is almost the same. The installation process and precautions are as follows: (1) When the installation size is determined, it should be installed according to the product size. Use the instructions or samples to ensure the installation size of the mechanical seal. (2) Before loading, the shaft (sleeve) and gland should be free of burrs, and the bearing should be in good condition; the seals, shaft, sealing cavity and gland should be cleaned. In order to reduce the conflict resistance, the part where the mechanical seal is installed on the shaft should be coated with a thin layer of oil for smoothness. Considering the compatibility of the rubber O-ring, if oil is not suitable, soapy water can be applied. The structure of the floating static ring without anti-rotation pin should not be oiled, and should be installed in the gland dry. (3) Install the static ring together with the gland on the shaft first, taking care not to collide with the shaft, and then install the moving ring assembly. The set screw of the spring seat or transmission seat should be tightened evenly in several times. Before the gland is not fixed, push the compensating ring by hand for axial tightening. After loosening, the compensating ring can automatically spring back without jamming, and then lock the gland bolts evenly. 4. Application (1) When the temperature of the transport medium is too high, too low, or rich in impurity particles, flammable, explosive, or toxic, it is necessary to take corresponding measures such as blocking, flushing, cooling, and filtering. (2) Turn the car by hand before running, pay attention to whether the torque is too large, whether there is friction or abnormal sound. (3) Pay attention to the direction of rotation, whether the coupling is centered, whether the addition of lubricating oil in the bearing part is appropriate, and whether the piping is accurate. (4) Before operation, first open the medium and cooling water valves to check whether the gas in the sealed chamber is completely discharged, so as to avoid leakage caused by static pressure, and then start the operation. (5) Whether the work is normal and stable after driving, whether there is abnormal torque caused by shaft rolling, abnormal noise and overheating.

Custom message