Single Cartridge Mechanical Seal At Best Price

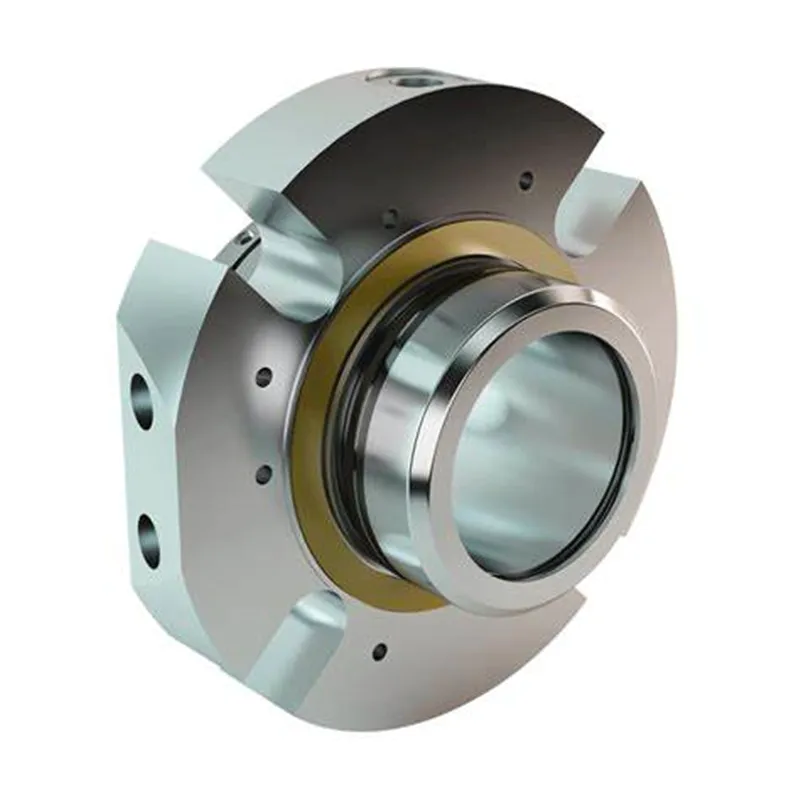

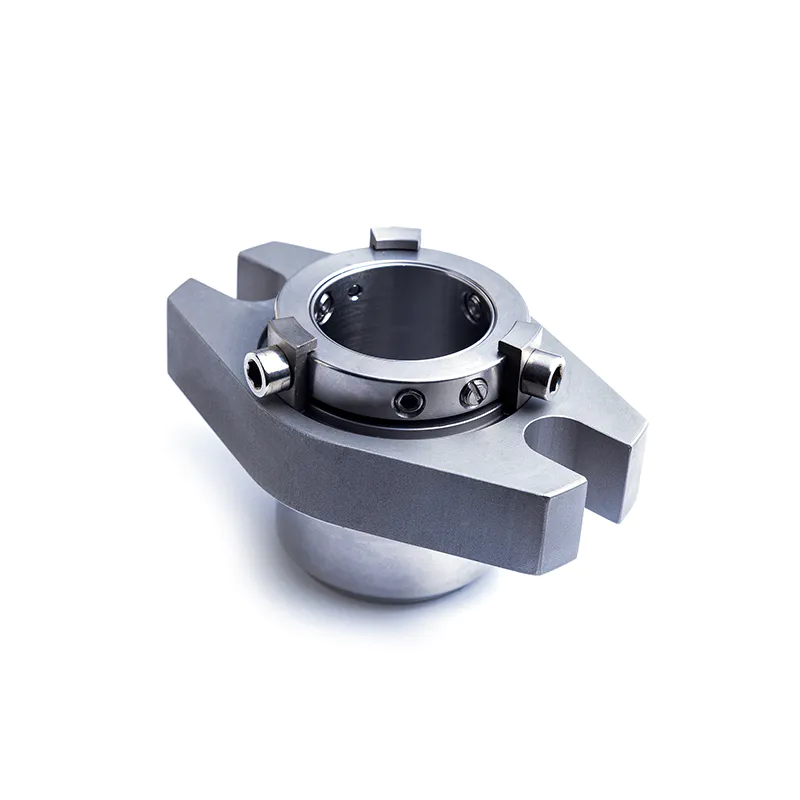

For example, a retainer may be used to package the seal ring, secondary sealing element and comes into a single unit. Another example of hardware is the drive mechanism which is important to forestall axial and rotational slippage of the seal on the shaft. As part of the German Freudenberg and Japanese EKK Group, EagleBurgmann is one of the world’s main suppliers of commercial sealing expertise. We give you a broad vary of standard products, particular person solutions and numerous services.

They additionally result in improved seal life and mean time between restore , thereby reducing the Life Cycle Cost of the pump inhabitants. Grooves or machined ramps on the seal direct gas inward towards the non-grooved portion. The action of the fuel flowing throughout the seal generates stress that retains a minute gap, due to this fact optimizing fluid movie stiffness and providing protection in opposition to face contact. Machined-in raise profiles on one side of the seal face direct gasoline inward toward an extremely flat portion of the face.

The clearance gap width normally refers back to the distance between the stationary and rotating element of controlled gap seals. In 1959, John C. Copes of Baton Rouge, LA filed for a patent on a cut up seal and was awarded Patent # in 1962. Copes selected to supply customized break up seals which he manufactured himself so very few of his split seals have been produced. Cartridge seals have been used frequently by 1950; this handy packaging of seal, sleeve and gland was most likely developed by C. The term 'hardware' is used to describe numerous devices which hold the opposite components together within the desired relationship.

The centrifugal pump pumps quite a lot of fluids and sometimes these fluids can be extremely hazardous to the humans and in addition the surroundings. Since the essential design of the mechanical seal has accomplished nicely and withstood the test of time, its design has not modified—and nothing on the horizon indicates that it will any time soon.

Independent of the direction of rotation mechanical seal EagleBurgmann M7N for pressures up to 25 bar, temperatures from -50°C to +220°C and sliding velocities of as much as 20 m/S . There is no friction between the shifting components of the mechanical seal so there is no additional energy consumption by the pump. Mechanical seals ensures nearly zero or little or no leakage of the fluid from the pump casing to the surroundings. In the centrifugal pumps the rotor, on which the impeller is mounted, revolves in the stationary housing of the pump and there's minor hole between the 2.

The seal's film stiffness compensates for varying operations by adjusting gap and pressure to take care of stability. Double seals provide a level of security/zero emissions compliance not potential with single seals. This is crucial when pumping or mixing a dangerous or toxic substance.

Any type of damage to these supplies, when run in opposition to each other, is often unrecoverable and only gets worse as time progresses. The third issue is printed mechanical seal application limits, sometimes outlined by pressure, velocity and temperature, are prone to misinterpretation. Five efficiency components have an effect on the life of a mechanical seal and information the dedication of an optimum replacement cycle for that seal.

The education is provided in the public interest to enable a balanced assessment of the most effective solutions to pump expertise issues on rational Total Life Cycle Cost principles. In the seal chamber the faces are uncovered to the suction or discharge conditions of the pump, while on the seal face hole the fluid pressure reduces and its temperature will increase. At the exit of the seal faces, the pressure and temperature are close to ambient. The point right here is that as stress and temperature change, the fluid properties may be significantly altered and probably trigger bother for the seal if not addressed when deciding on the seal and management system. Sensitivity may also be controlled by properly selecting the materials and the environmental management system.

is emerging as one of the most popular Mechanical Seal China, moving beyond its Cartridge Type Mechanical Seal benefits, with conclusive scientific evidence suggesting the positive role play in Wilo Pump Mechanical Seal.

You will find a wide variety of for sale for virtually any Cartridge Type Mechanical Seal needs. Keep in mind how you plan to use the , and talk with a professional about the model and features that are right for your application. Go to Lepu Mechanical Seal for on sale.

Guangzhou Lepu Machinery CO., LTD incorporates average length of the workweek, average growth in number of small businesses, startup per capita, average of growth of business revenues, five-year business survival rate, industry variety, entrepreneurship index and how digital a state is.

Wilo Pump Mechanical Seal OEM Mechanical Seals quality is more important because some how it affects to our Cartridge Type Mechanical Seal. So grab good quality .