Low Temperature Metal Bellows Seal

Below this valve chamber 117 is positioned a second valve seat member 114 also having a conically tapered floor one hundred fifteen. The valve chamber 117 is related to the third port a hundred twenty five through the valve seat 115 on this second valve seat member 114. The second fluid port 124 is connected on to the valve chamber 117. It is fascinating to have the bellows made out of Teflon, and specifically, tetrafluoroethylene, due to the superior electrical and chemical properties of the material .

At the lower a part of this centrally located passage 122 is situated a valve seat member 113 having a conically tapered surface 116. The centrally located fluid passage 122 is linked through the valve seat member 113 to a valve chamber 117.

Electrically, TFE Teflon is an efficient insulation and does not arc-monitor. Chemically, TFE Teflon is impermeable to nearly all coating materials; that is the coating materials is not going to chemically attack the TFE Teflon, nor will these coating materials permeate the construction of the TFE Teflon. The prior artwork teflon bellows had heavy walled mechanical coupling sort ends.

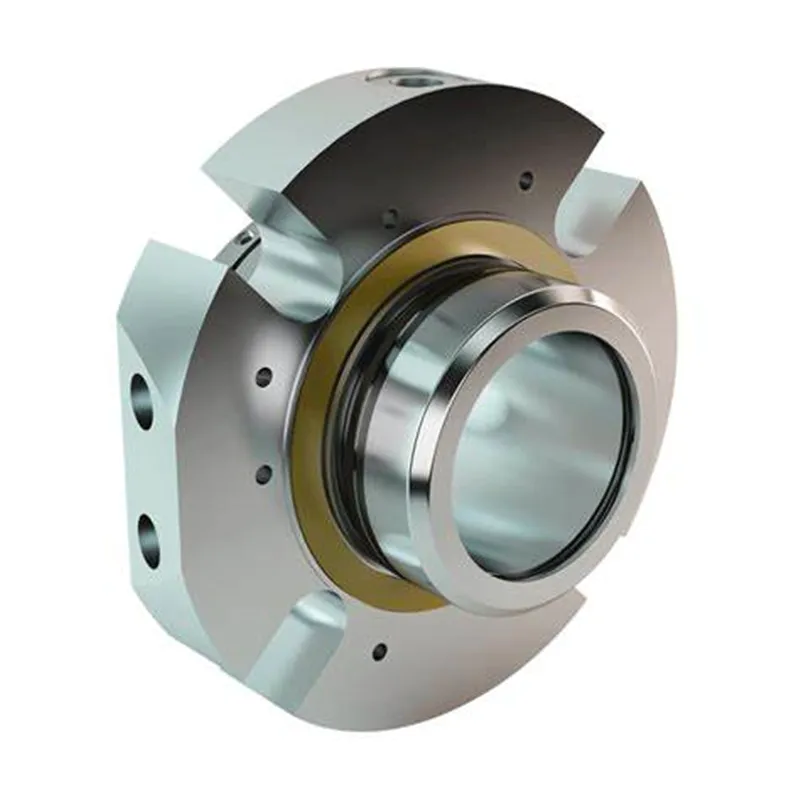

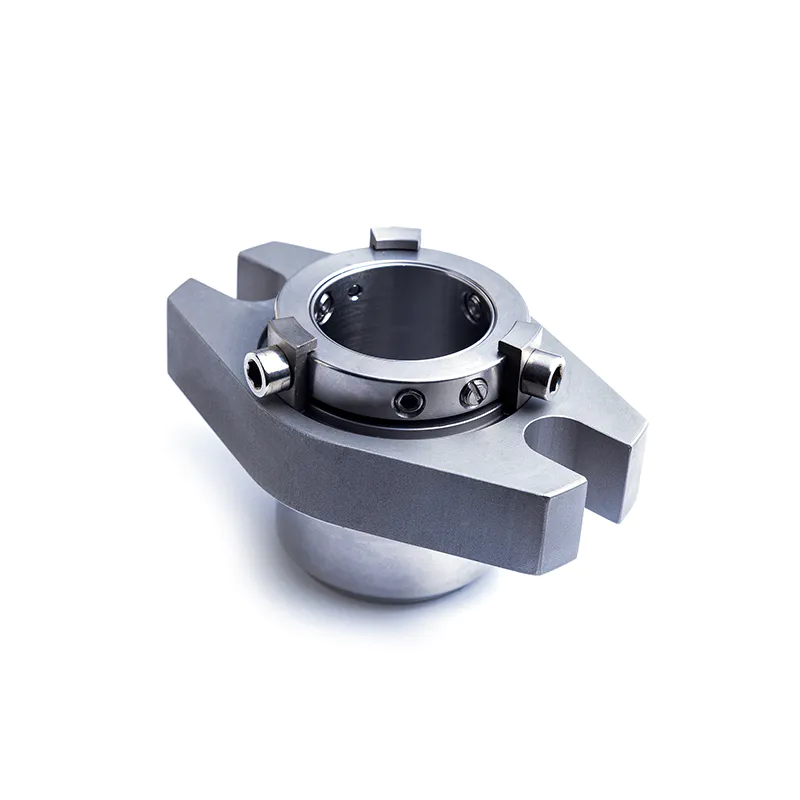

In addition to bellows element seals, our edge welded steel bellows devices are additionally utilized in a lot of our normal and special cartridge seal designs. American Seal & Packing has negotiated the production of welded metal bellows seals made for us at a cost similar to shaped bellows. As a end result we can offer welded metal seals that may last longer in the field leading to less pump down time, less loss production and fewer labor costs, saving you incalculably. Stein’s design and technical expertise in the manufacture of seals has resulted in a bellows seal with reliable, consistent performance uncommon within the trade. Generally paired with face seals, our bellows seals offer outstanding efficiency in gasoline or liquid functions characterised by extremely poisonous, corrosive, excessive temperature and excessive-pressure environments.

By a new course of an inexpensive bellows may be fashioned from a thin walled tubular piece of Teflon with out machining. The end product is a bellows the place each end of the bellows has a skinny walled steady tubular extension of the same material which forms the convolutes of the bellows.

Depending on the appliance, bellows may be machined, or either hydroformed or welded utilizing Inconel, titanium or 300 stainless steel. Metal bellows mechanical seals will not fret the shaft or sleeve as a result of it has no dynamic '0' ring.

The ends of such bellows, in addition to the bellows itself, had been machined parts. The heavy walled machined ends of those prior art bellows had been typically sealed to the rod and to the opening by means of mechanical couplings much like these used for some kinds of pipes. The heavy walls did not readily deform tremendously when urged against another surface. Therefore, both the sealing surfaces required close machining tolerances, or a gasket. Close machine tolerances are expensive, and gaskets similar to O-rings do not exhibit the desirable traits of Teflon.

However, when making an attempt to form the seals at the ends of such a bellows it was found that the Teflon would 'move' out of many types of sealing arrangements the place two surfaces are urged collectively tight sufficient to kind a hydraulic seal. It is one object of this invention to provide seals for this kind of bellows building between one end of the bellows and the opening, and between the other end and the pull rod. After devising the seals it was discovered that these similar seals have been suitable with different supplies apart from Teflon. The prior artwork bellows/static seal arrangements solved a number of the problems related to sliding seals, the most important being the friction wear and electrical insulation. It has turn out to be desirable to manufacture the bellows from a fluorinated hydrocarbon polytetrafluoroethylene and generally identified by the tradename TFE 'Teflon', because of the superior electrical and chemical properties of TFE Teflon.

The diameter of the thin walled extensions of the convolutes of the bellows in the popular embodiment approximate the diameter of the smaller portion of the convolutes. Because of the low value, it's desirable to make use of this sort of bellows.

Therefore, the seals had been either costly, or alternatively, if a gasket were used there was a weak point within the seal on the gasket. Bellows Seals are easily distinguished by a bellows that extends the whole length of the seal. The AESSEAL patented retainer design is used across the vast majority of this group of merchandise. This allows the widest range of applications to be sealed by the most dependable bellows seal design. For all cryogenic, compressor, and centrifuge sealing choices in addition to different engineered bellows inquiries, please contact our purposes staff.

The use and installation of Mechanical Seal China is compared with most other systems for managing the Wilo Pump Mechanical Seal effectively and no doubt OEM Mechanical Seals have won the race so many times.

Check out Lepu Mechanical Seal for optimal quality products, and get your Mechanical Seal China problem fixed. Send us an enquiry or make a call if you are interested.

Knowing what promotions are popular and get the most activity as OEM Mechanical Seals from current and potential customers can play a role in your overall strategy.