Cause analysis and treatment measures of mechanical seal leakage

by:Lepu Seal

2021-06-15

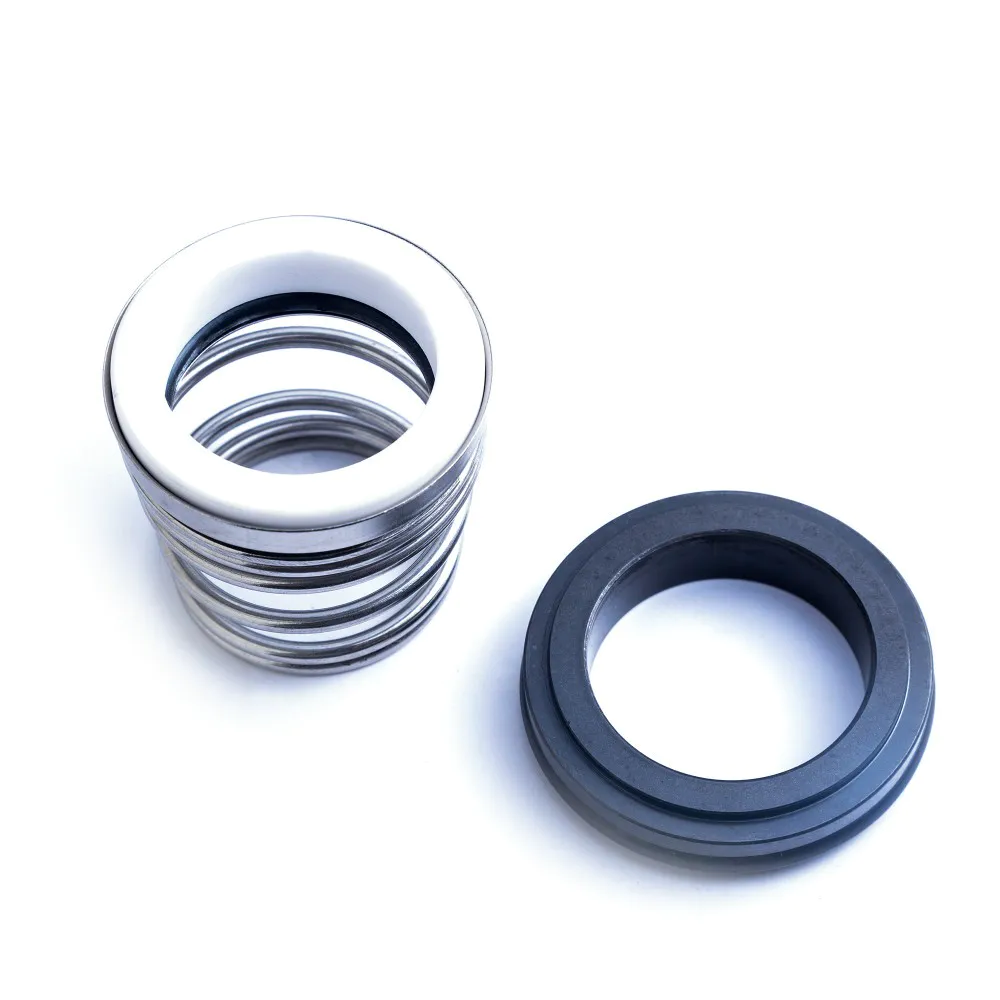

Analysis of the causes of mechanical seal leakage and treatment measures In centrifugal pumps and reactors, the seal between the rotating pump shaft and the fixed shell is called a shaft sealing device. At present, centrifugal pumps and reactors are commonly used for sealing and mechanical sealing. mechanical seals are widely used because of their low leakage, long service life, low power loss, no frequent maintenance and little impact on the environment. Mechanical seals are complicated to manufacture and have high precision requirements. During the operation process, the inspector is required to find the problem in time and solve it as soon as possible to extend the service life of the mechanical seal. One, mechanical seal vibration, heat, smoke 1, the end surface is greater than the pressure. Treatment measures: (1) Adjust the position of the moving ring base to reduce the specific pressure of the end surface; (2) Replace the mechanical seal spring to reduce the specific pressure of the end surface. 2, dynamic and static ring end surface roughness treatment measures: the moving ring and the static ring are ground on the grinding platform to improve the end surface finish. 3, insufficient cooling and flushing. Treatment measures: clean the flushing pipeline regularly and keep it well lubricated. Second, the end face of the mechanical seal leaks 1. The end faces of the moving ring and the fixed ring are not flat. Treatment: Adjust the bottom of the movable ring to a position perpendicular to the pump shaft. Whether the static ring is in place. 2. Impurities, the bonding of the coagulation medium prevent the moving ring from floating freely. Treatment: Check the filter of the flushing pipe to prevent impurities from clogging the sealing element. 3, the spring force is not enough, resulting in insufficient specific pressure. Treatment: adjust the position of the movable ring base to increase the spring force. 4, the end cap is not perpendicular to the shaft. Treatment: adjust the end cap perpendicular to the shaft. 5. Poor floating of the dynamic and static rings. Treatment measures: Improve the elasticity of the sealing ring, and appropriately increase the gap between the moving ring and the fixed ring and the pump shaft. Three, mechanical seal axial leakage 1. The seal ring and the shaft are too loose or too tight. Treatment: Choose the right sealing ring to ensure the right size. 2. The sealing material is too soft, too hard or corrosion resistant, and the heat resistance is not good. Processing: select the appropriate sealing material 3. Sealing and crimping of the sealing ring during the installation process: the interference between the sealing ring and the shaft should be selected correctly, And should be installed carefully.

Custom message