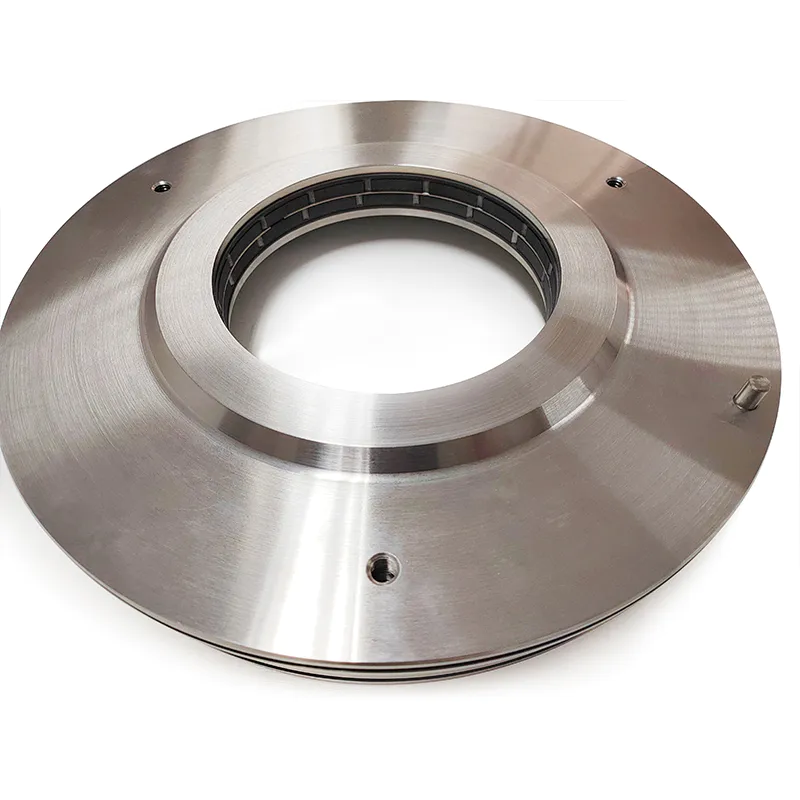

Dry Gas Seal

Basic knowledge of metal bellows mechanical seals

by:Lepu Seal

2022-08-03

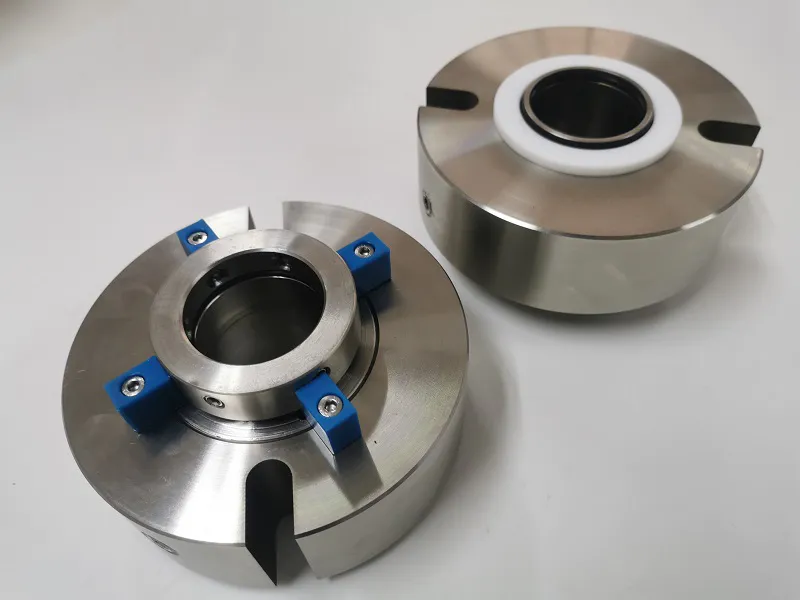

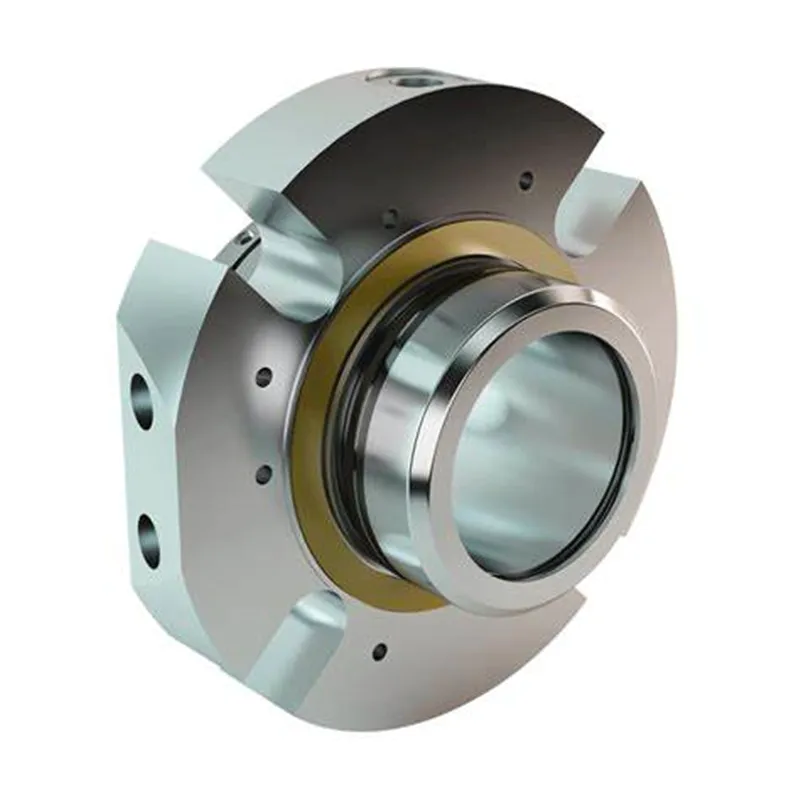

The metal bellows mechanical seal is a single-end, balanced, and arbitrarily rotated metal bellows seal. The moving ring O-ring and the flexible graphite ring do not compensate, so the bellows has no resistance to movement, and is suitable for high temperature, high Viscous medium.u200bu200b

Please select the friction pair material and auxiliary seal material of the bellows mechanical seal according to the actual working conditions.u200bu200b

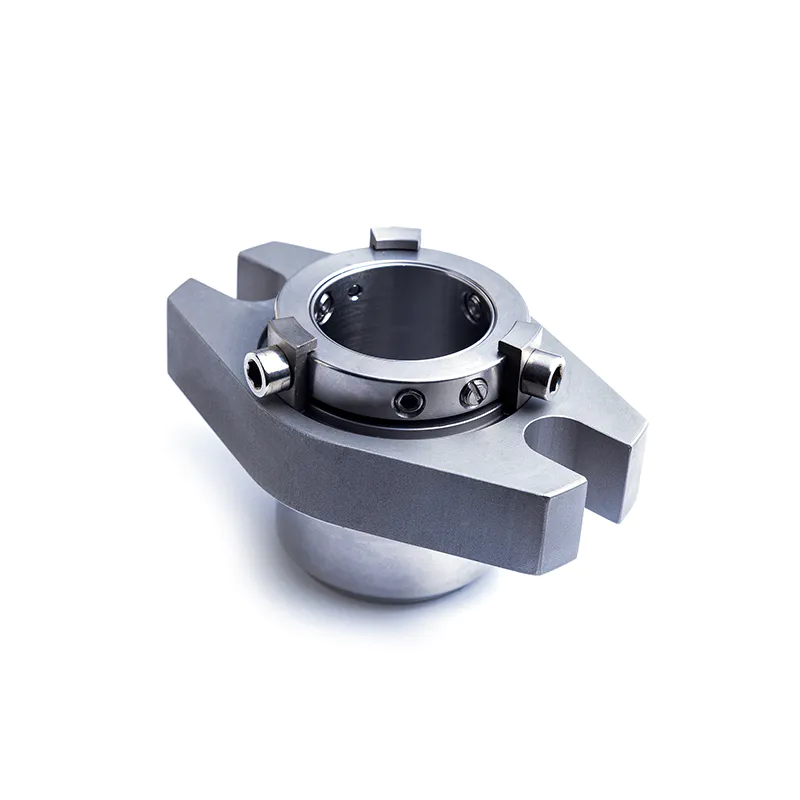

Metal bellows mechanical seal is suitable for high temperature and high speed conditions, and the transmission of torque does not affect the bellows. No other elastic elements form the secondary seal, and the non-compensating ring can be assembled as required. Application range of metal bellows mechanical seal: The application range of bellows type mechanical seal is very wide, from low temperature to high temperature, from neutral medium to corrosive medium, from low speed to high speed, and from ordinary to harsh working conditions. All of these can change the elastic modulus of the bellows by changing the geometry of the bellows (such as inner and outer diameter, wave plate thickness and wave number, etc.) and the elastic modulus of the material. According to the corrosive properties of the medium, different bellows materials are selected. For example, for neutral media (oil and water, etc.) with low working pressure and temperature, simple bellows made of rubber can be used to seal; in corrosive media (acid or alkali, etc.), bellows made of tetrafluoro can be used. Sealing; at high temperature and high speed, welded metal bellows mechanical seals can be used.

Main features of metal bellows mechanical seal: The function of the spring in the general mechanical seal (push ring type) is to maintain the compression and balance of the friction surface. The metal bellows mechanical seal not only acts as a spring, but also has a sealing structure, so the design does not require a moving ring O-ring. Compared with ordinary mechanical seals, metal bellows mechanical seals have many advantages, which can be summarized as follows. 1. High precision: The metal bellows acts as a spring, and is a combination of countless springs, so it solves the problem of ordinary springs deformed by centrifugal force, suitable for high rotation, and the sealing surface is evenly pressed, which is conducive to preventing leakage. 2. Vibration resistance and excellent flexibility: The bellows has high flexibility, because it absorbs vibration very well, so it has a very high adaptability to radial runout, axial clearance, vibration and swing, etc. Give way. 3. Simple structure: unlike the spring seal, which is composed of many parts, the structure is simple and the assembly is easy. 4. Adapt to various temperature conditions: the thermal expansion coefficient of the metal bellows is small, and it can be used at low temperature or high temperature. And there is no O-ring, free from temperature constraints, and the design is relatively free. 5. Suitable for high pressure: Because the bellows itself plays a balancing role, the sealing surface area can be set to reduce the fluid pressure and reduce the friction of the sealing surface. Thereby reducing the amount of heat and wear, can be used for high pressure. 6. Protect the machine (no shaft sleeve): The metal bellows mechanical seal has no O-ring, so there will be no wear of the shaft or sleeve caused by the abrasion of the O-ring. To protect the shaft, there is no need to install the shaft sleeve. 7. Adapt to corrosive fluids: The welded bellows are made of materials such as Hastelloy 276 with high corrosiveness, which avoids the problem of corrosion of springs and O-rings, thus achieving sealing. 8. No hanging: using ordinary push-ring mechanical seal, a small amount of leaked fluid solidifies and deposits in the air, preventing the moving ring O-ring from advancing. Therefore, the contact force of the sealing end face becomes weak or disappears, which leads to leakage. On the contrary, the metal bellows mechanical seal has no O-ring, even if there is solidified material, it will not be affected, it can rotate stably, and it can be extended for a long time. life. 9. Screw pumping function: The bellows itself has screw pumping function, which can effectively deal with fluids containing solid particles and help flushing.

Custom message